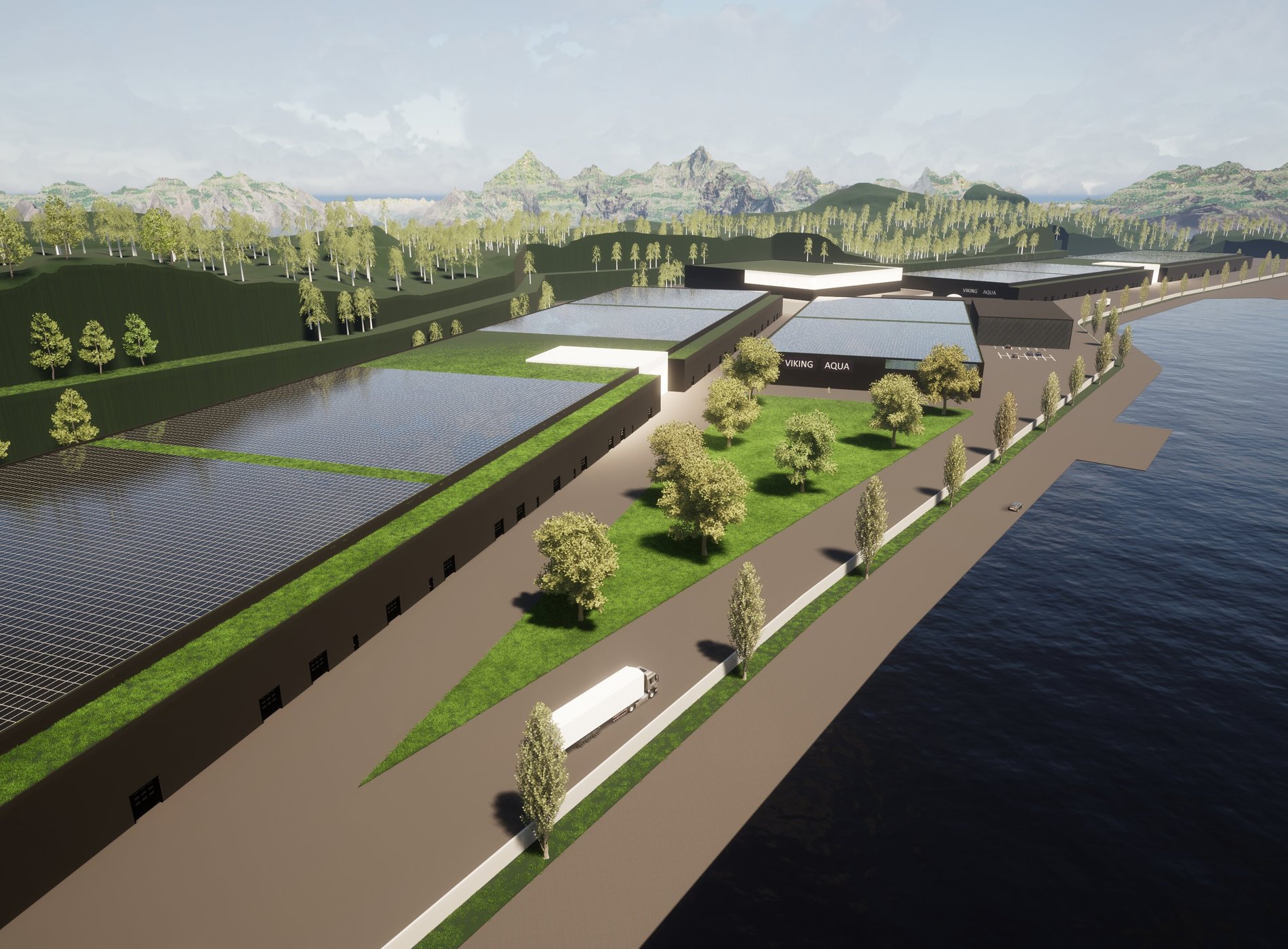

Eco-Bubble Design: The Viking Aqua Facility

Eco-Bubble Design: The Viking Aqua Facility

Photo by Anthony on Pexels

Our whole team at Viking Aqua and all our partners from architects, contractors, industrial equipment and technology suppliers, to industry and academic research partners, are used in achieving our concept of ‘Eco-Bubble’ Design. At the heart of the ‘Eco-Bubble’ is our salmon - everything centred around their development and welfare.

Located in the world’s best position for producing the highest quality sustainable Atlantic Salmon for the world’s consumers. Our facility is designed for an annual production of 33 000 tons of live, bubberly and healthy Atlantic Salmon. In addition to our salmon first environment, the building will contain our administration HQ, designed for people first, supporting the 80 employees.

An important aspect of the circular production of the Eco-Bubble is to control and lower water usage, and ensure water quality is to a maximum; secured using the latest developments in RAS systems. The required amount of freshwater of 5 000 m3 each day is produced from our local dam, while the 80 000 m3/day of high quality saltwater is pumped from 80 m depth in the Brandangersund, filtered and treated against plastics and chemicals, with rigorous monitoring before entering our facility.

Our ambition is that Eco-Bubble production will inspire radical improvements to ethical production and food globally.

You can get more information by reading 'Ethics & Environmental, Social & Corporate Governance'. Don't miss out on either the principles of the life cycle of ‘Our Salmon’ or the 4 key areas on ‘R&D’ we focus on.